Concurrent Engineering Design

Article on Design for Manufacturability. DESIGN FOR MANUFACTURABILITY ] This effective version of DFM will exceed cost goals in half the time by design. New: Leading-edge; Customized; Low-cost; Reach unlimited audiences anywhere; Schedule quickly; and Have time to work between4 four-hour sessions New article: DESIGN FOR MANUFACTURABILITY ARTICLE from the (2014, Productivity Press Copyright © 2017 by David M. Anderson Design for manufacturability (DFM) is the process of proactively designing products to (1) optimize all the manufacturing functions: fabrication, assembly, test, procurement, shipping, delivery, service, and repair, and (2) assure the best cost, quality, reliability, regulatory compliance, safety, time-to-market, and customer satisfaction.

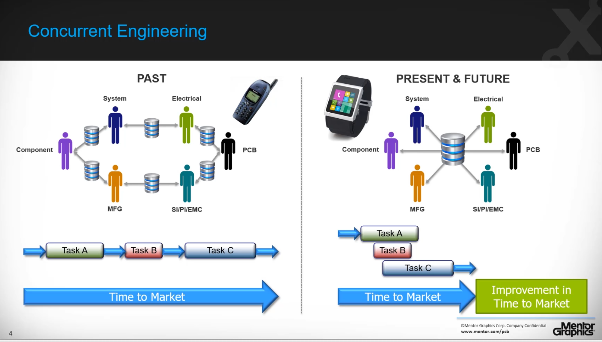

Kasauti zindagi ki episode 1. In other words, concurrent engineering aims at achieving throughput time reductions by planning and executing design and development activities in parallel,. Mitchell on demand 5.9 torrent.

Concurrent Engineering is the practice of concurrently developing products and their manufacturing processes. If existing processes are to be utilized, then the product must be design for these processes.

Concurrent Engineering Design Methodologies

If new processes are to be utilized, then the product and the process must be developed concurrently. Design for Manufacturability and Concurrent Engineering are proven design methodologies that work for any size company. Early consideration of manufacturing issues shortens product development time, minimizes development cost, and ensures a smooth transition into production for quick time to market.